Mechanical and Machine Tool Services cc (MMTS) is your trusted provider of quality engineering services for supplying, repairing and refurbishing mechanical components used throughout the plastics industry in Sub-Saharan Africa. Typically, we deal with barrels, screws, film blowing extruders, pipe extruders, blow moulders, injection moulders, plastics recycling machines, screen changers, breaker plates, spaghetti heads, die face pelletisers, film blowing dies, sheet dies, vacuum calibrators, water baths, pelletisers, shredders, granulators, tie bars, toggles, levers and host of other plastics related equipment.

We manufacture and repair barrels, screws, granulators, shredders, nibblers, screen changers, spaghetti heads, tie bars, toggles, levers, and do general engineering. We also offer on-site consulting and assessment services for all types of extruders and extrusion processes. We have in-house and industry partner design capability for the design and manufacture of screws, tips and barrels to suit your processing needs.

MMTS was started by Philippe Descroizilles in November 1998, servicing users of plastics and rubber machinery in South Africa and southern Africa. It was also active in the general engineering field, manufacturing hydraulic presses and platens.

In October 2008, the company based in Activia Park was purchased by Justin McPhail and Anthony Wilmot. Philippe retired from the company in March 2009 after an intensive 6 month handover period.

At the end of 2010, a decision was made to close the company at Activia Park engineering works, and to form a new company with Justin McPhail as the sole owner. Justin forged partnerships with all the key engineering materials and services suppliers, and MMTS continues to offer all engineering services to the plastics industry. Please refer to our Products and Services pages for further information.

MMTS offers a wide range of engineering products to the plastic conversion and recycling industry. This includes the manufacture of barrels, screws, granulators, nibblers, complete extruders, screen changers, and a host of parts and accessories.

In the process of extrusion, screws are used to process the raw material into a usable form to make the final product required. However, the performance of the screw is dependant on numerous factors, and we design and manufacture all types of barrels, single and twin. We have the capacity to handle barrels up to 6m in length from all manufacturers (1).

We can manufacture a nitrided NiCrAl steel barrel in approximately 2-3 weeks depending on it's size and design complexity. All work is done in-house except heat treatment which we subcontract to our specialist engineering partners.

We also manufacture bimetallic barrels from imported blanks that we keep in stock. A bimetallic barrel can be made in as little as a week and they offer superior wear resistance for customers who are using particularly abrasive materials such as recycled post-consumer films, titanium whiteners , calcium carbonate fillers and glass fillers.

We have the ability to design and manufacture almost any type of extruder screw, from cross-linked polyethylene to soap and even cellulose. We can manufacture a screw in as little as two weeks in our works, including heat treatment time. Bimetallic screws can be imported in any design from our international suppliers.

In the process of injection moulding, a screws inside a barrel is used to process the raw material into a usable form to make the final product required. However, the performance of the barrel is dependant on numerous factors, and we design and manufacture all types of barrels, both bimetallic and nitrided in construction. We have the capacity to handle barrels up to 6m in length from all manufacturers(1).

In the process of injection moulding, screws are used to process the raw material into a usable form to make the injection and the forming final product required within the die cavity. However, the performance of the screw is dependant on numerous factors, and we design and manufacture all types of screws, single and twin. All work is done in-house except heat treatment which we subcontract to our specialist engineering partners. We have the capacity to handle screws up to 6m in length from all manufacturers(1).

We manufacture both replacement and custom-designed tips sets for injection moulders. If you are experiencing problems with limited shot weight, poor cushion retention and long cycle times, we can design a tip to suit your process. All our tips are made with specialised NiCrAl nitriding steel and are heat treated and/or nitrided depending on the requirements. We also make specialised ring-less PVC injection moulder tips.

If you need to replace a broken or worn nozzle or want to increase the length of your nozzle, we can manufacture a new one either according to your design or a design by our experienced team.

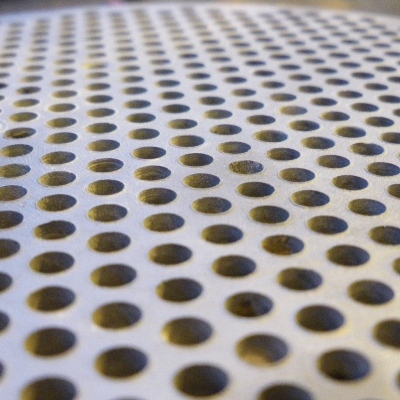

We make hardened tool steel breaker plates of any size and any number of holes.

We supply new, service, repair and recondition extruder, injection moulder, shredder and granulator gearboxes as part of our regular business. We can also assist with any type of industrial gearbox.

Rotary dough cutters are a new line of products for us in South Africa, and we have made several for a bakery in Johannesburg. They are used in the production of flat breads, pizza bases, pita breads, wraps and tortillas. We can design and manufacture a roller to cut almost any shape in your dough!

We manufacture manual and hydraulic screen changers for extruders from as small as 25mm to as large as 180mm in diameter.

If you need to replace a broken end cap or want to increase the bore of your injection moulder, we can manufacture an end cap either according to your design or a design by our experienced team.

Pitcture by Glenn McKechnie / CC BY-SA

Tie bar tolerances are critical to the efficient operation of injection moulders, and we are able to manufacture tie-bars up to 6m in length by machining, grinding, chroming and finishing to original equipment specification and quality levels.

We have manufactured numerous pipe and profile calibrators, both atmospheric and vacuum in design.

MMTS offers a wide range of engineering services to the plastic conversion and recycling industry. These services include the manufacture, repair and refurbishment of barrels, screws, granulators, shredders, nibblers, complete extruders, sheet dies, film dies, screen changers, die face pelletisers, gearboxes and a host of equipment either upstream or downstream of the extruder. We also offer the design of barrels and screws using the latest technologies from our experienced designers from Europe and Asia.

In the process of extrusion, injection moulding, blow moulding etc, screws are used to process the raw material into a usable form to make the final product required. However, the performance of the screw is dependant on the condition of the barrel, and we manufacture, repair and recondition most types of barrels, single and twin. All work is done in-house except heat treatment which we subcontract to our specialist engineering partners. We have the capacity to handle barrels up to 6m in length from all(1) manufacturers.

We will come to your premises and do a full assessment of the condition of your barrel and provide you with a report detailing the wear along the entire length. We will also evaluate the profile, straightness, concentricity, surface finish and hardness of the screw as advise of any potential problems. We do not normally charge our local and loyal customers for this service, and consider it a necessary part of maintaining the relationship with the client.

Screws are the heart of any extruder or injection moulder. We manufacture, repair and recondition all types of screws for processing a wide variety of material from virgin pE to dry sawdust. We are able to manufacture and repair check-rings, seating washers and tips for injection moulders. We have the capacity to handle screws up to 6m in length from all(2) manufacturers.

We will come to your premises and do a full assessment of the condition of your barrel and provide you with a report detailing the wear along the entire length. We will also evaluate the profile, straightness, concentricity, surface finish and hardness of the screw as advise of any potential problems. We do not normally charge our local and loyal customers for this service, and consider it a necessary part of maintaining the relationship with the client.

Tie bar tolerances are critical to the efficient operation of injection moulders, and we are able to refurbish tie-bars by grinding, chroming and re-finishing almost any tie-bar back to original specification. We can also join tie-bars and repair damaged threads.

We manufacture and sharpen blades for all types and sizes of granulators and shredders.

We supply and repair shredders of all types and sizes from manufacturers like Untha, hi-Tech and Satrind. We recondition shredder blades at a fraction of the cost of new ones.

We make and repair nibblers (single shaft shredders) to reduce lumps to small pieces or shavings depending on requirements.

We build extruders from those with a 15mm diameter screw for use in the medical field up to 180mm diameter for use in the field of recycling, film blowing, pipe and profile extrusion, sheet extrusion etc. We have made extruders for materials as diverse as cement, sawdust, charcoal and cellulose. We also recondition and re-build extruders as well as their barrels, screws, upstream and downstream equipment.

We make and recondition dies for film blowing, flat sheet, profiles etc. For all the dies we refurbish, we remove all defects and imperfections on the die-lip and cavity and thereafter we high polish and chrome plate the die to improve product quality and increase lifespan. For sheet dies we can install our customised die lip adjusting feature that allows much greater control over the lip gap and hence control over the film thickness across the length of the die.

We manufacture, repair and recondition screen changers, both manual and hydraulic. We have experience with all types including, sliding plate, pivoting plate and cylindrical changers. We manufacture breaker plates according to any specification. We can manufacture spaghetti heads with any number and size of strands for water-bath pelletising lines. We also supply wet and dry die face pelletisers.

At MMTS, we have one of the longest honing machines in our area of expertise and we are able to hone bores up to 6 metres in length in-house. We offer general honing services to the public provided that our honing machine has a break in the normal production schedule for our barrel refurbishment service.

We utilise several heat treatment and nitriding companies, and due to the volumes we process, we can negotiate better commercial terms. We can include your parts for nitriding in our batches and offer you better value.

We service, repair and recondition extruder, injection moulder, shredder and granulator gearboxes as part of our regular business, but we are able to assist with any type of industrial gearbox.

We undertake repairs to all types of equipment within our capacity. We have repaired and reconditioned calendar rolls, flock cutting machines, broken screws, broken barrels, damaged and worn gearboxes, sheet dies, film blowing dies, toggle systems, hydraulic cylinders, extruders, pumps, granulators, grinders, shredders, etc, to name but a few. We would be happy to hear about your requirements and needs. All work is done in-house apart from heat treatment, chrome plating etc, which we sub-contract to specialists.

We regularly make and refurbish screws or barrels for all extrusion and injection moulding machines, including those from Merritt , American Leistritz, Maileffer, John Royle, Lester, Haitian, Creator, Davis Standard, American Barmag, Boy, Yili, Chen Yu, Johnson, Tec, Wayne, Stokes, Bekum, Trueblood, Werner & Pfleiderer, Haida, Battenfeld, Gloucester, Engel, Husky, Uniloy, Erwepa, Brabender, Fisher, New Britian, Kawaguchi, Welding Engineers, Jinhu, Windmoller & Holscher and TMC, Autoinjectors, Nokia, Berlyn, New England/CFL, Olympia, SMC, Demag, Barmag, Epco, Parker, Welex, Entwistle, Sterling Davis, Hartig, Black Clawson, Shini, Tai Shin, Van Dorn, Milacron, Negri Bossi, Nrm, Toshiba, Dr Boy, Reifenhäuser, Maillefer, Nissei, JSW, Kiefel, Moslo, Nigata, Bandera, Kraus-Maffei, HPM, Gluco, Xaloy, Kautex, Klockner Windsor, Macchi, MPM, Kolsite, Hull, Farrel, Mitsubishi, Deacon, Victor, Macchi, Natco, Egan, Mingpai, Killian, Jomar, ICMA San Giorgio, Dolci, Hoover, Cincinnati Milacron, Placo, Reed, Sumitomo, Berstorff, Arburg, Jaco, Impco, Italia, Newbury, Bausano, Akron, Nelmor and Krespi. Trademarks or brand names are the property of their respective trademark holders.

(2) We repair all shredders, grinders and granulators, including those from Durl, Moditech, Blackfriars, Nelmor, Rapid, Foremost, Alpine, Untha, Hi-Tech, Sam Chin and Queens. Trademarks or brand names are the property of their respective trademark holders.

Tie bar tolerances are critical to the efficient operation of injection moulders, and we are able to refurbish tie-bars by grinding, chroming and re-finishing almost any tie-bar back to original specification. We can also join tie-bars and repair damaged threads.

Picture by Britton harper of Winona Van Norman, CC BY-SA 3.0, Link

Barrels hardly ever wear evenly, and therefore a worn barrel needs to be honed to the size of the most-worn section. The maximum amount that a barrel can be honed is dependent on a number of factors including the wall thickness of the barrel, the extrusion pressure generated, the material being processed and the geometric properties (compression ratios etc.) of the screw. All these factors must be considered before a barrel is honed, but in many cases the performance of the barrel and screw can be increased. It is critical that the barrel and screw are assessed and refurbished as a unit.

Yes. Nitrided Barrels are made from steel with a specific alloying of of chromium, aluminium and nickel. The nitriding process creates a layer of hardened material between 0.2 and 0.8mm thick on the surface of the material. Below this layer, the material remains mostly unaffected. The honing process removes the hardened layer, and allows another nitriding cycle to be applied to material.

Yes. In many cases, a screw will break at the smallest diameter, and the remainder of the screw will still be in good condition. We may be able to repair these screws so that you can put them back into service for a fraction of the cost of a new one. We typically make mechanical joins to ensure durability and reliability, although all screws should be replaced as good practice. It is also possible for us to join twin screws, but these repairs should be regarded as a interim measure which allows the plant to run while new screws are manufactured.

A check-ring is a hollow cylindrical device that is usually part of a tip assembly for an injection moulder screw. The check ring slides forwards during the charging stroke of the screw, allowing the melt to flow into the barrel ahead of the tip assembly. When the screw moves forward to inject the melt into the mould cavity, the check ring seals against the seating washer and prevents the melt from flowing back down the screw. This allows more consistent injection volume and allows the pressure in the mould (cushion) to be held for a period while the melt cools in the mould.

Pitcture by Glenn McKechnie / CC BY-SA

Yes. In many cases, a tie bar will break at the smallest diameter or at the threaded end of the tie bar nut, and the remainder of the tie bar will still be in good condition. We are able to repair these tie bars so that you can put them back into service for a fraction of the cost of a new one. The joins are stress relieved and heat treated to ensure durability and reliability. If required, we can manufacture anew tie bar or refurbish it by grinding, chroming and grinding it to OEM specification.

Yes. We are able to provide you with a turnkey plastic recycling line that will take post-consumer plastic items like bottles, crates and film and turn it into pellets for onward sale to plastic conversion company.

All we need is for you to estimate what volume and type of plastic that will be recycled each month so that we can configure and size the line appropriately. Then you can produce a business plan and obtain financing. Give us a call and we can discuss your requirements.

Corona treatment (sometimes referred to as air plasma) is a surface treatment process that improves the bonding characteristics of most materials such as: paper, films, foils, and polymers by raising surface energy (dyne level). Most plastics, such as polyethylene and polypropylene, have chemically inert and nonporous surfaces with low surface tensions causing them to be non-receptive to bonding with printing inks, coatings, and adhesives. Although results are invisible to the naked eye, surface treating modifies surfaces to improve adhesion. Polyethylene, polypropylene, nylon, vinyl, PVC, PET, metalized surfaces, foils, paper, and paperboard stocks are commonly treated by this method. It is safe, economical, and delivers high line speed throughput. Corona treatment is also suitable for the treatment of injection and blow molded parts, and is capable of treating multiple surfaces and difficult parts with a single pass. Source

polyethylene terephthalate (sometimes written poly(ethylene terephthalate)), commonly abbreviated PET, PETE, is a thermoplastic polymer resin of the polyester family and is used in synthetic fibres; beverage, food and other liquid containers; thermoforming applications; and engineering resins often in combination with glass fibre. Source

high-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a polyethylene thermoplastic made from petroleum. It takes 1.75 kilograms of petroleum (in terms of energy and raw materials) to make one kilogram of HDPE. HDPE is commonly recycled, and has the number "2" as its recycling symbol. In 2007, the global HDPE market reached a volume of more than 30 million tons. Source

Polypropylene or Polypropene (PP) is a thermoplastic polymer, made by the chemical industry and used in a wide variety of applications, including packaging, textiles (e.g. ropes, thermal underwear and carpets), stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes. An addition polymer made from the monomer propylene, it is rugged and unusually resistant to many chemical solvents, bases and acids.

Low-density polyethylene (LDPE) is a thermoplastic made from petroleum. It was the first grade of polyethylene, produced in 1933 by Imperial Chemical Industries (ICI) using a high pressure process via free radical polymerisation. Its manufacture employs the same method today. LDPE is commonly recycled, and has the number "4" as its recycling symbol. Source

Polystyrene, sometimes abbreviated PS, is an aromatic polymer made from the aromatic monomer styrene, a liquid hydrocarbon that is commercially manufactured from petroleum by the chemical industry. Polystyrene is one of the most widely used kinds of plastic.

Polystyrene is a thermoplastic substance, which is in solid (glassy) state at room temperature, but flows if heated above its glass transition temperature (for molding or extrusion), and becoming solid again when cooling off. Pure solid polystyrene is a colourless, hard plastic with limited flexibility. It can be cast into molds with fine detail. Polystyrene can be transparent or can be made to take on various colours.

Solid polystyrene is used in disposable cutlery, plastic models, CD and DVD cases, and smoke detector housings. Products made from foamed polystyrene are nearly ubiquitous, for example packing materials, insulation, and foam drink cups.

Polystyrene can be recycled, and has the number "6" as its recycling symbol. Unrecycled polystyrene, which does not biodegrade, is often abundant in the outdoor environment, particularly along shores and waterways, and is a form of pollution. Source

Polimerek / Public domain

Polybutylene terephthalate (PBT) is a thermoplastic engineering polymer that is used as an insulator in the electrical and electronics industries. It is a thermoplastic (semi-)crystalline polymer, and a type of polyester. PBT is resistant to solvents, shrinks very little during forming, is mechanically strong, heat-resistant up to 150&176;C (or 200&176;C with glass-fibre reinforcement) and can be treated with flame retardants to make it noncombustible. It was developed by Britain's Imperial Chemical Industries (ICI).

PBT is closely related to other thermoplastic polyesters. Compared to PET (polyethylene terephthalate), PBT has slightly lower strength and rigidity, slightly better impact resistance, and a slightly lower glass transition temperature. PBT and PET are sensitive to hot water above 60&176;C (140&176;F). PBT and PET need UV protection if used outdoors, and most grades of these polyesters are flammable, although additives can be used to improve both UV and flammability properties. Source

polyvinyl chloride, commonly abbreviated PVC, is the third most widely used thermoplastic polymer after polyethylene and polypropylene. Around the world, over 50% of PVC manufactured is used in construction. As a building material, PVC is cheap, durable, and easy to assemble. The PVC world market grew with an average rate of approximately 5% in the last year and will probably reach a volume of 40 million tons by the year 2016.

It can be made softer and more flexible by the addition of plasticizers, the most widely-used being phthalates. In this form, it is used in clothing and upholstery, and to make flexible hoses and tubing, flooring, to roofing membranes, and electrical cable insulation. It is also commonly used in figurines and in inflatable products such as waterbeds, pool toys, and inflatable structures. Source

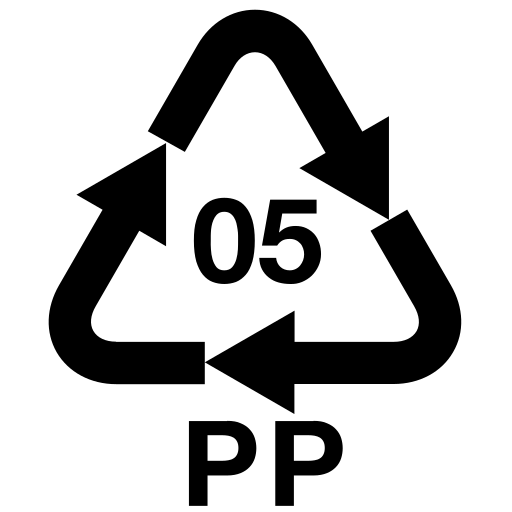

A polymer is a substance or material consisting of very large molecules, or macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins. Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. Their consequently large molecular mass, relative to small molecule compounds, produces unique physical properties including toughness, high elasticity, viscoelasticity, and a tendency to form amorphous and semicrystalline structures rather than crystals. Source

H Padleckas / Public domain

A polyolefin is a type of polymer produced from a simple olefin (also called an alkene with the general formula CnH2n) as a monomer. For example, polyethylene is the polyolefin produced by polymerizing the olefin ethylene. Polypropylene is another common polyolefin which is made from the olefin propylene. Source

polyolefins are impossible to join by solvent cementing because they have excellent chemical resistance and can only be adhesively bonded after surface treatment because they have very low surface energies. They are also extremely inert chemically and exhibit decreased strength at lower temperatures.

Polyolefin is used for blown film as well as rash guards or under garments for wetsuits. Polyolefin eloastomer POE is used as a main ingredient in the molded flexible foam technology such as in the fabrication of self skinned footwear (think Crocs shoes), seat cushions, arm rests and spa pillows etc. Source

Rotor DB / Public domain

Natural rubber is an elastomer (an elastic hydrocarbon polymer) originally derived from a milky colloidal suspension, or latex, found in the sap of some plants. The purified form of natural rubber is the chemical polyisoprene, which can also be produced synthetically. Synthetic rubber is often used as a covering for rollers in the film extrusion and printing industry. Source

Nitrile rubber, or Buna-N, is a synthetic rubber copolymer of acrylonitrile (ACN) and butadiene. Nitrile is often used as a covering for rollers in the film extrusion and printing industry. Some trade names are: Nipol, Krynac and Europrene. Source

Wikipedia user Akane 700 / CC BY-SA

Neoprene or polychloroprene is a family of synthetic rubbers that are produced by polymerization of chloroprene. Neoprene in general has good chemical stability, and maintains flexibility over a wide temperature range. It is used in a wide variety of applications, coverings for rollers in the film extrusion and printing industry, such as laptop sleeves, orthopedic braces (wrist, knee, etc.), electrical insulation, liquid and sheet applied elastomeric membranes or flashings, and car fan belts. Source

Roughness is a measure of the texture of a surface (the finish after a manufacturing process). It is quantified by the vertical deviations of a real surface from its ideal form. If these deviations are large, the surface is rough; if they are small the surface is smooth.

Roughness plays an important role in determining how a real object will interact with its environment. Rough surfaces usually wear more quickly and have higher friction coefficients than smooth surfaces (see tribology). Roughness is often a good predictor of the performance of a mechanical component, since irregularities in the surface may form nucleation sites for cracks or corrosion.

Although roughness is usually undesirable, it is difficult and expensive to control in manufacturing. Decreasing the roughness of a surface will usually increase exponentially its manufacturing costs. This often results in a trade-off between the manufacturing cost of a component and its performance in application. Source

Emok / Public domain

Honing is a manufacturing process that produces a precision surface on a workpiece by scrubbing an abrasive stone against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but may also improve surface texture.

Honing is classified as an abrasive machining manufacturing process. As with all abrasive machining processes, material is cut away from the workpiece using abrasive grains. In the case of honing, the grains are bound together with an adhesive to form a honing stone (or hone). Generally, honing grains are irregularly shaped and about 10 to 50 micrometers in diameter (300 to 1,500 mesh grit). Smaller grain sizes produce a smoother surface on the workpiece.

A honing stone is similar to a grinding wheel in many ways, but honing stones are usually more friable so that they conform to the shape of the workpiece as they wear in. To counteract their friability, honing stones may be treated with wax or sulfur to improve life; wax is usually preferred for environmental reasons.

Any abrasive material may be used to create a honing stone, but the most commonly used are corundum, silicon carbide, CBN or diamond. The choice of abrasive material is usually driven by the characteristics of the workpiece material. In most cases, corundum or silicon carbide are acceptable, but extremely hard workpiece materials must be honed using superabrasives. Source

Nitriding is a process which introduces nitrogen into the surface of a material. It is used in metallurgy, for example, for case hardening treatment of predominantly steel but also for titanium, aluminium and molybdenum. Nitriding is widely used in automotive, mechanical and aeronautical engineering. Typical components receiving this metallurgical process are gears, crankshafts, camshafts, cam followers, valve parts, extruder screws and barrels, die-casting tools, forging dies, extrusion dies, injectors and plastic-mould tools.

All nitriding processes enrich the surface of a material with nitrogen. Processes are named by the medium used to donate nitrogen. The three main methods used are gas nitriding, liquid or salt bath nitriding or ion (plasma) nitriding.

A nitrided barrel is usually made from a carbon steel with a combination of nickel, chromium and aluminium to produce an alloy that most readily accepts the nitriding process.

A bimetallic barrel has a hardened alloy layer fused to the inner bore of the barrel. The hardened layer is intruduced into a barrel blank as a powder. The barrel is placed in a high temperature furnace that subjects the powder to temperature of more than 1100 deg C while spinning the barrel, which fuses them together. Barrel cooling is carefully controlled on removal from the furnace and this results in a super-hard, highly uniform lining in the bore. The inner layer is then precision honed and the resutling bore lining is at least 1.5mm thick.

Users Cbuckley, Jpowell on en.wikipedia / Public domain

Plastic is the general common term for a wide range of synthetic or semisynthetic organic amorphous solid materials suitable for the manufacture of industrial products. Plastics are typically polymers of high molecular weight, and may contain other substances to improve performance and/or reduce costs.

There are two types of plastics: thermoplastics and thermosets. Thermoplastics, if exposed to enough heat, will melt. Thermosets will keep their shape until they are charred and burnt. Some examples of thermoplastics are grocery bags, piano keys and some automobile parts. Examples of thermosets are children's dinner sets and circuit boards.

Common plastics and uses :

Special-purpose plastics :

Pigment is a concentrated colourant, supplied in a powdered form generally used for smaller runs or specialised applications such as Rotational Moulding. These are usually compatible with HDPE, PP, LLDPE, LDPE, EVA, AVS, PVC, GP Styrene, although not exlcusively.

Bleeding: the situation in which parts of the colouring constituents either stain an adjacent contact material or are released into a surrounding solvent.

Blooming: migration of pigment or additive particles in the component to the surface which results in the appearance of a 'haze' or bloom on the surface of the product. Generally confined to a few organic pigments and some UV stabilizers this effect can take some time to develop. It is more likely to be seen in masterbatches where the higher concentrations of colourants and additives may exceed their compatibility with the carrier polymer.

Blue Wool Scale: (ISO 105-B01-1988) is a means of measuring the colour fastness to natural daylight of a colour by comparing it to a blue wool standard. It was originally developed to compare the fastness properties of textile dyes. Expressed on a scale of 1-8, where 1 is the lowest value, the next digit corresponds to twice the fastness level of the previous digit. i.e. double the exposure time at the same exposure level.

Colour Index: a system of classifying colourants by their chemical type. For example titanium dioxide is C.I. Pigment White 6 and a fluorescent yellow dye is C.I. Solvent Yellow 98.

Dispersing aids: additives incorporated into the masterbatch formulation to promote dispersion and development of the active constituents. These can work in a number of ways, reducing friction, wetting and separating the pigment particles, helping to break down pigment aggregates, improving melt rheology, lubricating the particles to name a few.

Dispersion: defines the quality of the breakdown of pigment aggregates and separation of pigment particles to maximize colour development. Usually referred to in the general terms of good and bad. Poor dispersion results in pigment specks being present in the final part and low colour strength. Pigment specks can lead to low impact strength and process failures in blow moulding or film extrusion. In metallic and pearl colours poor dispersion can also be (erroneously) applied to the streaking caused by the pigment platelets being orientated in different directions.

Distribution: describes how well the masterbatch pellets are spread throughout the base polymer. Poor distribution can appear as variations in colour between successive mouldings.

Dyes: powdered colourants that are soluble in the molten polymer matrix (see pigment).

Fillers: solid additives, usually inert inorganic compounds (e.g. Chalk, Talc etc) added to plastics and masterbatches to increase polymer bulk or reduce costs. Some fillers are incorporated to produce specific physical properties, for example stiffness, temperature resistance or raised specific gravity in polymer compounds.

Fish eyes: contamination of incompatible material resulting in scale like appearance (frequently found with use of regrind material)

Granule: standard pellet size of 3.2mm

Grey Scale: (ISO105-A02-1993) is a scale from 1-5 (where 5 is no change) used to describe colour change due to weathering and other environmental exposure.

Heavy metal pigments: the coloured salts of heavy metals (lead and cadmium) that make good, economical pigments. Concerns about heavy metals in the waste/recycling chain and in toys and food containers have led to their control by legislation in some applications and their replacement with organic substitutes.

Homogenisation: the term to describe the evenness of mixing of the constituents in the compound. Poor homogenisation appears as colour streaks in the parts.

Lamination: occurs when there is stratification of the polymer due to poor homogenisation of the masterbatch. Usually a processing problem, it is often blamed on masterbatch incompatibility although it can be created by inappropriate use of universal masterbatches.

Let Down Ratio (LDR): the level at which a master batch is incorporated into the base polymer. Hence an LDR of 3 (%) is 97 % polymer, 3% masterbatch.

Melt fracture: describes the alternation of adhesion/slip between the extrudate and the side of the extruder barrel or die on processing plant giving a 'sharkskin' effect on the products, especially film and profile or hose extrusions.

Metamerism: the term used to describe the phenomena in which two colours are a good match under one illumination but are not a good match when illuminated under a different light source. This is due to different pigment combinations in the composition of each colour and the different absorption and reflection characteristics of each pigment under the differing illuminations. To avoid metamerism it is important to specify the illumination conditions under which the final part will be used, especially if it will be alongside other materials (fabrics, painted items etc) that it is required to match in colour.

Micro-pellet: granules with a standard size of 0.8mm,

Migration: a term applied to the mobility of colourants usually attributed to the partial solubility in the polymer of one of the components of the colour. It can appear as 'bleeding' or 'blooming'.

Mini-pellet: granules with a standard size of 1.1mm

Monopigment concentrates: special masterbatches featuring high pigment loadings up to 65% developed for in-house processors who want to minimize contamination and reduce cleaning costs, or those wishing to produce their own colours or masterbatches

Multi-functional masterbatches: composite masterbatches that combine colour with functional additives, for example UV stabilizers, anti-oxidants, anti-static additives.

Pigment: powdered colourants that are dispersed through the polymer matrix (see dyes).

Plate out: this is the separation during processing and deposition on the metal surfaces of the equipment of one or more components of a material. It appears as staining on processing equipment and is sometimes referred to as 'mould staining' although it can also affect extruder screws and dies. Usually it is attributed to a limited compatibility of part of the formulation

Polymer specific masterbatch: a masterbatch in which the carrier for the colourant(s) or active additives is the same polymeric type as the polymer it is to be used in (see universal).

Prill: spherical beads typically 1.2 to 1.5mm diameter - presents a high surface area that gives better distributive mixing of pigments and additives and hence significantly enhanced homogenization. Smaller spherical pellets present higher surface areas that give better distributive mixing of pigments and additives and hence significantly enhanced homogenization. For applications requiring only low levels of colour or additive the low LDRs involved can lead to poor distribution due to the small number of masterbatch pellets present in the mix. As the masterbatch pellet size decreases the number of pellets rises for any given LDR, greatly improving their distribution and the quality of the final product. The smallest pellets also are of great benefit when adding colour or additives to powdered base materials. Addition of conventionally sized masterbatch to powders such as PVC blends can lead to separation after mixing; Mini- or Micro-pellets are much closer in size to the powders and are much less likely to separate during conveying or feeding into the process equipment.

Slip: as the name implies this refers to the 'slippery' nature of a polymer surface (low co-efficient of friction). Also used to describe a family of additives that increase this property.

Universal masterbatch: a highly concentrated masterbatch in which the 'carrier' or 'binder' is formulated from ingredients selected for their compatibility with a range of polymers enabling it to be used in a number of different polymers. It should be recognized that use of a universal masterbatch to colour several different polymer types is unlikely to result in components that are all the same shade. This is due to the different base colours of polymers and the effects that some polymer types have on colourant chemistry.

Weld line: the meeting of two material flows in a moulding. This can be a source of potential failure of the part under stress if the two flow fronts do not retain sufficient energy to mix well when they meet. Weld lines can be particularly noticeable in mouldings containing metallic or pearlescent colours. In these cases the laminar nature of the pigments results in their being oriented in a particular direction by the flow of the polymer, leading to an unsightly boundary line where the flows meet. Visibility and strength of weld lines can be optimized by tool design and moulding conditions.

Pigment is a concentrated colourant supplied in a powdered form generally used for smaller runs or specialised applications such as Rotational Moulding. These are usually compatible with HDPE, PP, LLDPE, LDPE, EVA, AVS, PVC, GP Styrene, although not exlcusively.

Masterbatch (MB) is a solid additive for plastic used for colouring plastics (colour masterbatch) or imparting other properties to plastics (additive masterbatch). A liquid dosage form is called liquid colour. Masterbatch is a concentrated mixture of pigments and/or additives encapsulated during a heat process into a carrier resin which is then cooled and cut into a granular shape. Masterbatch allows the processor to colour raw polymer economically during the plastics manufacturing process.

Is this Mechanical and Machine Tool Services cc the same business as Mechanical and Machine Tool Services (Pty) Ltd? Yes, at the end of 2010, the company was re-formed into a Close Corporation by Justin after the closure of the Activia Park factory. We provide all the services we have in the past.

Does the old 011 828 1653 or 011 828 1081 telephone number still work? No. We have switched to mobile numbers because they are more reliable. More contact info on our Contact page.

Does the old 011 828 5987 fax number still work? No, we do all written communication via e-mail and whatsapp. Please refer to the info on our Contact page.

This page contains links to organisations that are important within our business environment. These links open in a new browser window. All logos are the copyright of the respective organisations.

Packaging SA

Packaging SA

The Packaging Council of South Africa (PACSA) was founded in 1984 and has been replaced by a new industry body called Packaging SA. Packaging SA is closely associated with The Institute of Packaging South Africa (IPSA). Packaging SA is a voluntary industry body. Its members are in two broad categories, Converters and Associates. The Converters represent some 70% of the revenue generated by the industry. Associates are in effect the major raw material suppliers, material organizations, brand owners, retailers and other organizations and associations with interests in the packaging industry. Collectively this body directly employs some 60 000 people in South Africa.

Packaging SA represents views of its members on national issues with particular focus on environmental matters.

petco

petco

PETCO, the PET Recycling Company, is a company that takes Extended Producer Responsibility (EPR) for the end-of-life solution for the PET bottle sector on a collaborative basis, both financially and operationally.

PETCO supports recyclers with community programmes, educational material and awareness programmes on recycling. PETCO promotes recycling efficiency in the production, design, conversion, collection and recycling of post-consumer PET plastic.

They are an industry-driven and industry-financed environmental solution for post-consumer PET. Funded by a voluntary recycling fee paid by our members who purchase PET resin, we're proud to say that, since our inception in 2004, we've helped make a truly positive impact in South Africa.

The Plastics Insititute of South Africa

The Plastics Insititute of South Africa

The role of PISA is to assist co-operation and the exchange of knowledge between persons engaged or interested in the technologies of plastics, high polymers and related subjects, or in the development or application of these products and to enable such persons to meet and correspond. They also aim to advance the standards and methods of education in the fields of plastics, to promote development of the art, science and technologies of these subjects and to encourage research in their development and application.

British Plastics Federation

British Plastics Federation

The British Plastics Federation (BPF) is the world's longest running plastics trade association, established in 1933 to represent the UK industry.

It has over 450 members that span across the supply chain. This includes plastics recyclers, polymer producers and suppliers, additive manufacturers, services providers, end users, plastics processors and machinery manufacturers, in total representing over 80% of the industry by turnover.

The main purpose of the BPF is to promote a successful UK plastics sector, which it does by providing membership services to the different BPF groups, including projects, events, updates, research and other activities.

Their Plastipedia web site is a good source of information.

Plastics | SA

Plastics | SA

Plastics|SA represents all sectors of the South African plastics industry, including polymer producers and importers, converters, machine suppliers, fabricators and recyclers. Together with their associations, they play an active role in the growth and development of the SA industry and strive to address plastics related issues, influence role-players and make plastics the material of choice.

SA Polymer Technology

SA Polymer Technology

SA Polymer Technology (previously SA Plastics, Composites & Rubber magazine) was launched in 2002 by Summit Publishing, based in Cape Town and owned by publisher Martin Wells. Martin has more than 30 years experience as a journalist and editor focusing on the polymers industry and is an active member of the Plastics Institute of Southern Africa.

Plastics Technology

Plastics Technology

Plastics Technology provides authoritative content on plastics processing practices, tips, techniques, troubleshooting, technical advances, product developments, market insights and industry news. Their content is aimed at plastics processors, both custom and captive operations.

The Institute of Packaging (SA)

The Institute of Packaging (SA)

IPSA aims to promote high standards and professionalism in the packaging industry, to provide opportunities for networking and education and to promote the recognition of packaging as a profession.

Institute of Waste Management of Southern Africa

Institute of Waste Management of Southern Africa

The Institute of Waste Management of Southern Africa (IWMSA) is a multi-disciplinary non-profit association that is committed to supporting professional waste management practices.

Expanded Polystyrene Association of South Africa

Expanded Polystyrene Association of South Africa

As the association representing expanded polystyrene manufacturers, raw material suppliers and equipment suppliers in South Africa, it is EPSASA's mission to promote and grow the expanded polystyrene market.

Southern African Plastic Pipe Manufacturers Association

Southern African Plastic Pipe Manufacturers Association

The purpose/mission of SAPPMA is to create absolute customer confidence in the plastics pipe Industry, thereby ensuring long term sustainability and dynamic growth.

National Recycling Forum

National Recycling Forum

The National Recycling Forum (NRF) is a non-profit organisation created to promote the recovery and recycling of recyclable materials in South Africa.

South African Waste Information Centre

South African Waste Information Centre

This Waste Information Centre provides the public, business, industry and government with access to information on the management of waste in South Africa.

merSETA

merSETA

The merSETA is one of the 21 Sector Education and Training Authorities (SETAs) established to promote skills development in terms of the Skills Development Act of 1998 (as amended). The 21 SETAs broadly reflect different sectors of the South African economy. The merSETA encompasses Manufacturing, Engineering and Related Services.

Metal and Engineering Industries Bargaining Council

Metal and Engineering Industries Bargaining Council

The Metal and Engineering Industries Bargaining Council (MEIBC) is a statutory body created under the Labour Relations Act (LRA) to provide for the co-regulation of stable and productive employment relations in the metal and engineering industries.

SACCI Business Confidence Index

SACCI Business Confidence Index

The Business Confidence Index is generated monthly by SACCI as a measure the level of business confidence within the South African economy. The report includes commentary on the current state of the economy, as well as other economic indicators.

South African Insitute of Industrial Engineering

South African Insitute of Industrial Engineering

The field of Industrial Engineering deals with the engineering of industrial or industrious undertakings. Modern Industrial Engineering is concerned with the integration of resources and processes into cohesive strategies, structures and systems for the effective and efficient production of quality goods and services. Source

SA Good News

SA Good News

In South Africa, we're sitting on the edge of greatness, but many of us know little of the progress that's been achieved since 1994. Fewer still have a sense of what the future holds.

EngNet

EngNet

EngNet® is a powerful Directory/Search Engine/Buyers Guide Service aimed specifically at the Engineering Industry to enable Engineers, Technicians, Tradesmen, etc. to find information and communicate effectively with suppliers in the Engineering Industry.

Our technical support and administration team are there to help you with all aspects of running your plastics conversion or recycling business. From extrusion of medical grade IV tubing, to granulation of post-consumer PVC, our team has the knowledge and experience to get the most out of your production process.

BSc (Hons) Industrial Engineering

Owner and Technical Consultant

tel. +27 (0)83 761 4571

mail. adminmmts.co.za

Our technical support and administration team are there to help you with all aspects of running your plastics conversion or recycling business. From extrusion of medical grade IV tubing, to granulation of post-consumer PVC, our team has the knowledge and experience to get the most out of your production process.

Main line: +27 (0)83 761 4571

adminmmts.co.za

+27 (0)83 761 4571

PO Box 4195

Northcliff

2115

Gauteng

South Africa