Picture by Britton harper of Winona Van Norman, CC BY-SA 3.0, Link

Barrels hardly ever wear evenly, and therefore a worn barrel needs to be honed to the size of the most-worn section. The maximum amount that a barrel can be honed is dependent on a number of factors including the wall thickness of the barrel, the extrusion pressure generated, the material being processed and the geometric properties (compression ratios etc.) of the screw. All these factors must be considered before a barrel is honed, but in many cases the performance of the barrel and screw can be increased. It is critical that the barrel and screw are assessed and refurbished as a unit.

Yes. Nitrided Barrels are made from steel with a specific alloying of of chromium, aluminium and nickel. The nitriding process creates a layer of hardened material between 0.2 and 0.8mm thick on the surface of the material. Below this layer, the material remains mostly unaffected. The honing process removes the hardened layer, and allows another nitriding cycle to be applied to material.

Yes. In many cases, a screw will break at the smallest diameter, and the remainder of the screw will still be in good condition. We may be able to repair these screws so that you can put them back into service for a fraction of the cost of a new one. We typically make mechanical joins to ensure durability and reliability, although all screws should be replaced as good practice. It is also possible for us to join twin screws, but these repairs should be regarded as a interim measure which allows the plant to run while new screws are manufactured.

A check-ring is a hollow cylindrical device that is usually part of a tip assembly for an injection moulder screw. The check ring slides forwards during the charging stroke of the screw, allowing the melt to flow into the barrel ahead of the tip assembly. When the screw moves forward to inject the melt into the mould cavity, the check ring seals against the seating washer and prevents the melt from flowing back down the screw. This allows more consistent injection volume and allows the pressure in the mould (cushion) to be held for a period while the melt cools in the mould.

Pitcture by Glenn McKechnie / CC BY-SA

Yes. In many cases, a tie bar will break at the smallest diameter or at the threaded end of the tie bar nut, and the remainder of the tie bar will still be in good condition. We are able to repair these tie bars so that you can put them back into service for a fraction of the cost of a new one. The joins are stress relieved and heat treated to ensure durability and reliability. If required, we can manufacture anew tie bar or refurbish it by grinding, chroming and grinding it to OEM specification.

Yes. We are able to provide you with a turnkey plastic recycling line that will take post-consumer plastic items like bottles, crates and film and turn it into pellets for onward sale to plastic conversion company.

All we need is for you to estimate what volume and type of plastic that will be recycled each month so that we can configure and size the line appropriately. Then you can produce a business plan and obtain financing. Give us a call and we can discuss your requirements.

Corona treatment (sometimes referred to as air plasma) is a surface treatment process that improves the bonding characteristics of most materials such as: paper, films, foils, and polymers by raising surface energy (dyne level). Most plastics, such as polyethylene and polypropylene, have chemically inert and nonporous surfaces with low surface tensions causing them to be non-receptive to bonding with printing inks, coatings, and adhesives. Although results are invisible to the naked eye, surface treating modifies surfaces to improve adhesion. Polyethylene, polypropylene, nylon, vinyl, PVC, PET, metalized surfaces, foils, paper, and paperboard stocks are commonly treated by this method. It is safe, economical, and delivers high line speed throughput. Corona treatment is also suitable for the treatment of injection and blow molded parts, and is capable of treating multiple surfaces and difficult parts with a single pass. Source

polyethylene terephthalate (sometimes written poly(ethylene terephthalate)), commonly abbreviated PET, PETE, is a thermoplastic polymer resin of the polyester family and is used in synthetic fibres; beverage, food and other liquid containers; thermoforming applications; and engineering resins often in combination with glass fibre. Source

high-density polyethylene (HDPE) or polyethylene high-density (PEHD) is a polyethylene thermoplastic made from petroleum. It takes 1.75 kilograms of petroleum (in terms of energy and raw materials) to make one kilogram of HDPE. HDPE is commonly recycled, and has the number "2" as its recycling symbol. In 2007, the global HDPE market reached a volume of more than 30 million tons. Source

Polypropylene or Polypropene (PP) is a thermoplastic polymer, made by the chemical industry and used in a wide variety of applications, including packaging, textiles (e.g. ropes, thermal underwear and carpets), stationery, plastic parts and reusable containers of various types, laboratory equipment, loudspeakers, automotive components, and polymer banknotes. An addition polymer made from the monomer propylene, it is rugged and unusually resistant to many chemical solvents, bases and acids.

Low-density polyethylene (LDPE) is a thermoplastic made from petroleum. It was the first grade of polyethylene, produced in 1933 by Imperial Chemical Industries (ICI) using a high pressure process via free radical polymerisation. Its manufacture employs the same method today. LDPE is commonly recycled, and has the number "4" as its recycling symbol. Source

Polystyrene, sometimes abbreviated PS, is an aromatic polymer made from the aromatic monomer styrene, a liquid hydrocarbon that is commercially manufactured from petroleum by the chemical industry. Polystyrene is one of the most widely used kinds of plastic.

Polystyrene is a thermoplastic substance, which is in solid (glassy) state at room temperature, but flows if heated above its glass transition temperature (for molding or extrusion), and becoming solid again when cooling off. Pure solid polystyrene is a colourless, hard plastic with limited flexibility. It can be cast into molds with fine detail. Polystyrene can be transparent or can be made to take on various colours.

Solid polystyrene is used in disposable cutlery, plastic models, CD and DVD cases, and smoke detector housings. Products made from foamed polystyrene are nearly ubiquitous, for example packing materials, insulation, and foam drink cups.

Polystyrene can be recycled, and has the number "6" as its recycling symbol. Unrecycled polystyrene, which does not biodegrade, is often abundant in the outdoor environment, particularly along shores and waterways, and is a form of pollution. Source

Polimerek / Public domain

Polybutylene terephthalate (PBT) is a thermoplastic engineering polymer that is used as an insulator in the electrical and electronics industries. It is a thermoplastic (semi-)crystalline polymer, and a type of polyester. PBT is resistant to solvents, shrinks very little during forming, is mechanically strong, heat-resistant up to 150&176;C (or 200&176;C with glass-fibre reinforcement) and can be treated with flame retardants to make it noncombustible. It was developed by Britain's Imperial Chemical Industries (ICI).

PBT is closely related to other thermoplastic polyesters. Compared to PET (polyethylene terephthalate), PBT has slightly lower strength and rigidity, slightly better impact resistance, and a slightly lower glass transition temperature. PBT and PET are sensitive to hot water above 60&176;C (140&176;F). PBT and PET need UV protection if used outdoors, and most grades of these polyesters are flammable, although additives can be used to improve both UV and flammability properties. Source

polyvinyl chloride, commonly abbreviated PVC, is the third most widely used thermoplastic polymer after polyethylene and polypropylene. Around the world, over 50% of PVC manufactured is used in construction. As a building material, PVC is cheap, durable, and easy to assemble. The PVC world market grew with an average rate of approximately 5% in the last year and will probably reach a volume of 40 million tons by the year 2016.

It can be made softer and more flexible by the addition of plasticizers, the most widely-used being phthalates. In this form, it is used in clothing and upholstery, and to make flexible hoses and tubing, flooring, to roofing membranes, and electrical cable insulation. It is also commonly used in figurines and in inflatable products such as waterbeds, pool toys, and inflatable structures. Source

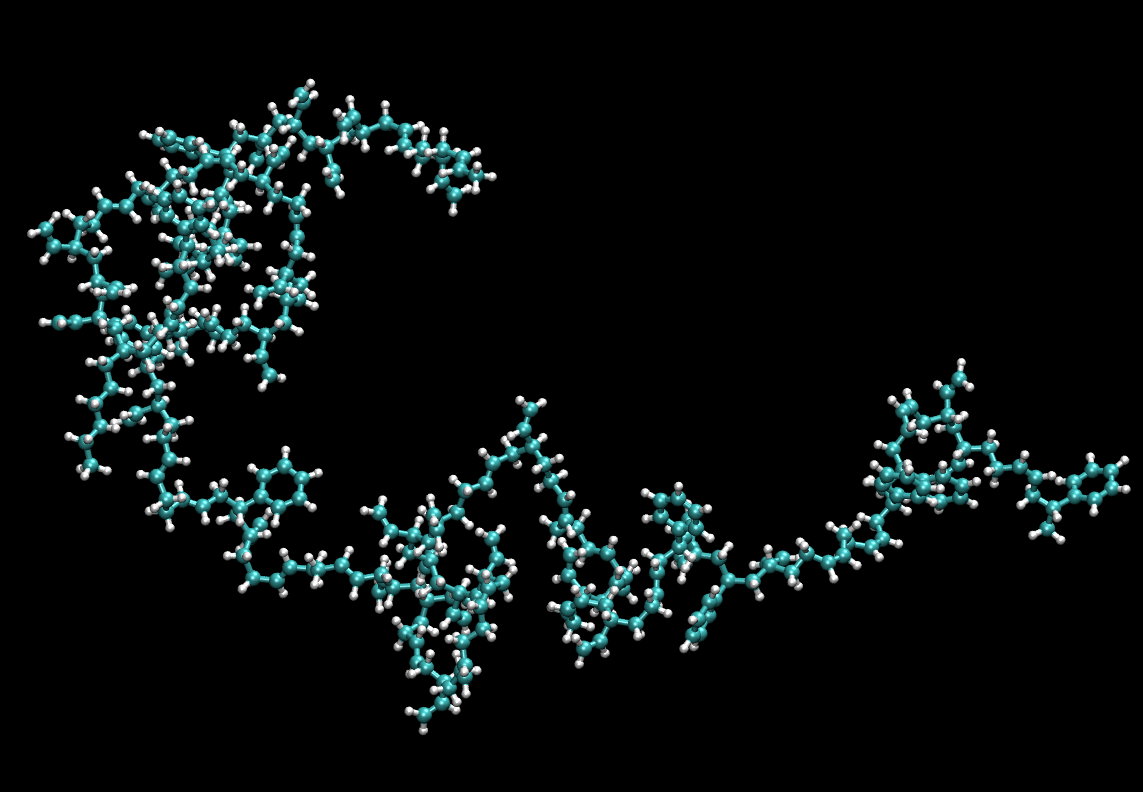

A polymer is a substance or material consisting of very large molecules, or macromolecules, composed of many repeating subunits. Due to their broad spectrum of properties, both synthetic and natural polymers play essential and ubiquitous roles in everyday life. Polymers range from familiar synthetic plastics such as polystyrene to natural biopolymers such as DNA and proteins. Polymers, both natural and synthetic, are created via polymerization of many small molecules, known as monomers. Their consequently large molecular mass, relative to small molecule compounds, produces unique physical properties including toughness, high elasticity, viscoelasticity, and a tendency to form amorphous and semicrystalline structures rather than crystals. Source

H Padleckas / Public domain

A polyolefin is a type of polymer produced from a simple olefin (also called an alkene with the general formula CnH2n) as a monomer. For example, polyethylene is the polyolefin produced by polymerizing the olefin ethylene. Polypropylene is another common polyolefin which is made from the olefin propylene. Source

polyolefins are impossible to join by solvent cementing because they have excellent chemical resistance and can only be adhesively bonded after surface treatment because they have very low surface energies. They are also extremely inert chemically and exhibit decreased strength at lower temperatures.

Polyolefin is used for blown film as well as rash guards or under garments for wetsuits. Polyolefin eloastomer POE is used as a main ingredient in the molded flexible foam technology such as in the fabrication of self skinned footwear (think Crocs shoes), seat cushions, arm rests and spa pillows etc. Source

Rotor DB / Public domain

Natural rubber is an elastomer (an elastic hydrocarbon polymer) originally derived from a milky colloidal suspension, or latex, found in the sap of some plants. The purified form of natural rubber is the chemical polyisoprene, which can also be produced synthetically. Synthetic rubber is often used as a covering for rollers in the film extrusion and printing industry. Source

Nitrile rubber, or Buna-N, is a synthetic rubber copolymer of acrylonitrile (ACN) and butadiene. Nitrile is often used as a covering for rollers in the film extrusion and printing industry. Some trade names are: Nipol, Krynac and Europrene. Source

Wikipedia user Akane 700 / CC BY-SA

Neoprene or polychloroprene is a family of synthetic rubbers that are produced by polymerization of chloroprene. Neoprene in general has good chemical stability, and maintains flexibility over a wide temperature range. It is used in a wide variety of applications, coverings for rollers in the film extrusion and printing industry, such as laptop sleeves, orthopedic braces (wrist, knee, etc.), electrical insulation, liquid and sheet applied elastomeric membranes or flashings, and car fan belts. Source

Roughness is a measure of the texture of a surface (the finish after a manufacturing process). It is quantified by the vertical deviations of a real surface from its ideal form. If these deviations are large, the surface is rough; if they are small the surface is smooth.

Roughness plays an important role in determining how a real object will interact with its environment. Rough surfaces usually wear more quickly and have higher friction coefficients than smooth surfaces (see tribology). Roughness is often a good predictor of the performance of a mechanical component, since irregularities in the surface may form nucleation sites for cracks or corrosion.

Although roughness is usually undesirable, it is difficult and expensive to control in manufacturing. Decreasing the roughness of a surface will usually increase exponentially its manufacturing costs. This often results in a trade-off between the manufacturing cost of a component and its performance in application. Source

Emok / Public domain

Honing is a manufacturing process that produces a precision surface on a workpiece by scrubbing an abrasive stone against it along a controlled path. Honing is primarily used to improve the geometric form of a surface, but may also improve surface texture.

Honing is classified as an abrasive machining manufacturing process. As with all abrasive machining processes, material is cut away from the workpiece using abrasive grains. In the case of honing, the grains are bound together with an adhesive to form a honing stone (or hone). Generally, honing grains are irregularly shaped and about 10 to 50 micrometers in diameter (300 to 1,500 mesh grit). Smaller grain sizes produce a smoother surface on the workpiece.

A honing stone is similar to a grinding wheel in many ways, but honing stones are usually more friable so that they conform to the shape of the workpiece as they wear in. To counteract their friability, honing stones may be treated with wax or sulfur to improve life; wax is usually preferred for environmental reasons.

Any abrasive material may be used to create a honing stone, but the most commonly used are corundum, silicon carbide, CBN or diamond. The choice of abrasive material is usually driven by the characteristics of the workpiece material. In most cases, corundum or silicon carbide are acceptable, but extremely hard workpiece materials must be honed using superabrasives. Source

Nitriding is a process which introduces nitrogen into the surface of a material. It is used in metallurgy, for example, for case hardening treatment of predominantly steel but also for titanium, aluminium and molybdenum. Nitriding is widely used in automotive, mechanical and aeronautical engineering. Typical components receiving this metallurgical process are gears, crankshafts, camshafts, cam followers, valve parts, extruder screws and barrels, die-casting tools, forging dies, extrusion dies, injectors and plastic-mould tools.

All nitriding processes enrich the surface of a material with nitrogen. Processes are named by the medium used to donate nitrogen. The three main methods used are gas nitriding, liquid or salt bath nitriding or ion (plasma) nitriding.

A nitrided barrel is usually made from a carbon steel with a combination of nickel, chromium and aluminium to produce an alloy that most readily accepts the nitriding process.

A bimetallic barrel has a hardened alloy layer fused to the inner bore of the barrel. The hardened layer is intruduced into a barrel blank as a powder. The barrel is placed in a high temperature furnace that subjects the powder to temperature of more than 1100 deg C while spinning the barrel, which fuses them together. Barrel cooling is carefully controlled on removal from the furnace and this results in a super-hard, highly uniform lining in the bore. The inner layer is then precision honed and the resutling bore lining is at least 1.5mm thick.

Users Cbuckley, Jpowell on en.wikipedia / Public domain

Plastic is the general common term for a wide range of synthetic or semisynthetic organic amorphous solid materials suitable for the manufacture of industrial products. Plastics are typically polymers of high molecular weight, and may contain other substances to improve performance and/or reduce costs.

There are two types of plastics: thermoplastics and thermosets. Thermoplastics, if exposed to enough heat, will melt. Thermosets will keep their shape until they are charred and burnt. Some examples of thermoplastics are grocery bags, piano keys and some automobile parts. Examples of thermosets are children's dinner sets and circuit boards.

Common plastics and uses :

Special-purpose plastics :

Pigment is a concentrated colourant, supplied in a powdered form generally used for smaller runs or specialised applications such as Rotational Moulding. These are usually compatible with HDPE, PP, LLDPE, LDPE, EVA, AVS, PVC, GP Styrene, although not exlcusively.

Bleeding: the situation in which parts of the colouring constituents either stain an adjacent contact material or are released into a surrounding solvent.

Blooming: migration of pigment or additive particles in the component to the surface which results in the appearance of a 'haze' or bloom on the surface of the product. Generally confined to a few organic pigments and some UV stabilizers this effect can take some time to develop. It is more likely to be seen in masterbatches where the higher concentrations of colourants and additives may exceed their compatibility with the carrier polymer.

Blue Wool Scale: (ISO 105-B01-1988) is a means of measuring the colour fastness to natural daylight of a colour by comparing it to a blue wool standard. It was originally developed to compare the fastness properties of textile dyes. Expressed on a scale of 1-8, where 1 is the lowest value, the next digit corresponds to twice the fastness level of the previous digit. i.e. double the exposure time at the same exposure level.

Colour Index: a system of classifying colourants by their chemical type. For example titanium dioxide is C.I. Pigment White 6 and a fluorescent yellow dye is C.I. Solvent Yellow 98.

Dispersing aids: additives incorporated into the masterbatch formulation to promote dispersion and development of the active constituents. These can work in a number of ways, reducing friction, wetting and separating the pigment particles, helping to break down pigment aggregates, improving melt rheology, lubricating the particles to name a few.

Dispersion: defines the quality of the breakdown of pigment aggregates and separation of pigment particles to maximize colour development. Usually referred to in the general terms of good and bad. Poor dispersion results in pigment specks being present in the final part and low colour strength. Pigment specks can lead to low impact strength and process failures in blow moulding or film extrusion. In metallic and pearl colours poor dispersion can also be (erroneously) applied to the streaking caused by the pigment platelets being orientated in different directions.

Distribution: describes how well the masterbatch pellets are spread throughout the base polymer. Poor distribution can appear as variations in colour between successive mouldings.

Dyes: powdered colourants that are soluble in the molten polymer matrix (see pigment).

Fillers: solid additives, usually inert inorganic compounds (e.g. Chalk, Talc etc) added to plastics and masterbatches to increase polymer bulk or reduce costs. Some fillers are incorporated to produce specific physical properties, for example stiffness, temperature resistance or raised specific gravity in polymer compounds.

Fish eyes: contamination of incompatible material resulting in scale like appearance (frequently found with use of regrind material)

Granule: standard pellet size of 3.2mm

Grey Scale: (ISO105-A02-1993) is a scale from 1-5 (where 5 is no change) used to describe colour change due to weathering and other environmental exposure.

Heavy metal pigments: the coloured salts of heavy metals (lead and cadmium) that make good, economical pigments. Concerns about heavy metals in the waste/recycling chain and in toys and food containers have led to their control by legislation in some applications and their replacement with organic substitutes.

Homogenisation: the term to describe the evenness of mixing of the constituents in the compound. Poor homogenisation appears as colour streaks in the parts.

Lamination: occurs when there is stratification of the polymer due to poor homogenisation of the masterbatch. Usually a processing problem, it is often blamed on masterbatch incompatibility although it can be created by inappropriate use of universal masterbatches.

Let Down Ratio (LDR): the level at which a master batch is incorporated into the base polymer. Hence an LDR of 3 (%) is 97 % polymer, 3% masterbatch.

Melt fracture: describes the alternation of adhesion/slip between the extrudate and the side of the extruder barrel or die on processing plant giving a 'sharkskin' effect on the products, especially film and profile or hose extrusions.

Metamerism: the term used to describe the phenomena in which two colours are a good match under one illumination but are not a good match when illuminated under a different light source. This is due to different pigment combinations in the composition of each colour and the different absorption and reflection characteristics of each pigment under the differing illuminations. To avoid metamerism it is important to specify the illumination conditions under which the final part will be used, especially if it will be alongside other materials (fabrics, painted items etc) that it is required to match in colour.

Micro-pellet: granules with a standard size of 0.8mm,

Migration: a term applied to the mobility of colourants usually attributed to the partial solubility in the polymer of one of the components of the colour. It can appear as 'bleeding' or 'blooming'.

Mini-pellet: granules with a standard size of 1.1mm

Monopigment concentrates: special masterbatches featuring high pigment loadings up to 65% developed for in-house processors who want to minimize contamination and reduce cleaning costs, or those wishing to produce their own colours or masterbatches

Multi-functional masterbatches: composite masterbatches that combine colour with functional additives, for example UV stabilizers, anti-oxidants, anti-static additives.

Pigment: powdered colourants that are dispersed through the polymer matrix (see dyes).

Plate out: this is the separation during processing and deposition on the metal surfaces of the equipment of one or more components of a material. It appears as staining on processing equipment and is sometimes referred to as 'mould staining' although it can also affect extruder screws and dies. Usually it is attributed to a limited compatibility of part of the formulation

Polymer specific masterbatch: a masterbatch in which the carrier for the colourant(s) or active additives is the same polymeric type as the polymer it is to be used in (see universal).

Prill: spherical beads typically 1.2 to 1.5mm diameter - presents a high surface area that gives better distributive mixing of pigments and additives and hence significantly enhanced homogenization. Smaller spherical pellets present higher surface areas that give better distributive mixing of pigments and additives and hence significantly enhanced homogenization. For applications requiring only low levels of colour or additive the low LDRs involved can lead to poor distribution due to the small number of masterbatch pellets present in the mix. As the masterbatch pellet size decreases the number of pellets rises for any given LDR, greatly improving their distribution and the quality of the final product. The smallest pellets also are of great benefit when adding colour or additives to powdered base materials. Addition of conventionally sized masterbatch to powders such as PVC blends can lead to separation after mixing; Mini- or Micro-pellets are much closer in size to the powders and are much less likely to separate during conveying or feeding into the process equipment.

Slip: as the name implies this refers to the 'slippery' nature of a polymer surface (low co-efficient of friction). Also used to describe a family of additives that increase this property.

Universal masterbatch: a highly concentrated masterbatch in which the 'carrier' or 'binder' is formulated from ingredients selected for their compatibility with a range of polymers enabling it to be used in a number of different polymers. It should be recognized that use of a universal masterbatch to colour several different polymer types is unlikely to result in components that are all the same shade. This is due to the different base colours of polymers and the effects that some polymer types have on colourant chemistry.

Weld line: the meeting of two material flows in a moulding. This can be a source of potential failure of the part under stress if the two flow fronts do not retain sufficient energy to mix well when they meet. Weld lines can be particularly noticeable in mouldings containing metallic or pearlescent colours. In these cases the laminar nature of the pigments results in their being oriented in a particular direction by the flow of the polymer, leading to an unsightly boundary line where the flows meet. Visibility and strength of weld lines can be optimized by tool design and moulding conditions.

Pigment is a concentrated colourant supplied in a powdered form generally used for smaller runs or specialised applications such as Rotational Moulding. These are usually compatible with HDPE, PP, LLDPE, LDPE, EVA, AVS, PVC, GP Styrene, although not exlcusively.

Masterbatch (MB) is a solid additive for plastic used for colouring plastics (colour masterbatch) or imparting other properties to plastics (additive masterbatch). A liquid dosage form is called liquid colour. Masterbatch is a concentrated mixture of pigments and/or additives encapsulated during a heat process into a carrier resin which is then cooled and cut into a granular shape. Masterbatch allows the processor to colour raw polymer economically during the plastics manufacturing process.

Is this Mechanical and Machine Tool Services cc the same business as Mechanical and Machine Tool Services (Pty) Ltd? Yes, at the end of 2010, the company was re-formed into a Close Corporation by Justin after the closure of the Activia Park factory. We provide all the services we have in the past.

Does the old 011 828 1653 or 011 828 1081 telephone number still work? No. We have switched to mobile numbers because they are more reliable. More contact info on our Contact page.

Does the old 011 828 5987 fax number still work? No, we do all written communication via e-mail and whatsapp. Please refer to the info on our Contact page.