MMTS offers a wide range of engineering services to the plastic conversion and recycling industry. These services include the manufacture, repair and refurbishment of barrels, screws, granulators, shredders, nibblers, complete extruders, sheet dies, film dies, screen changers, die face pelletisers, gearboxes and a host of equipment either upstream or downstream of the extruder. We also offer the design of barrels and screws using the latest technologies from our experienced designers from Europe and Asia.

In the process of extrusion, injection moulding, blow moulding etc, screws are used to process the raw material into a usable form to make the final product required. However, the performance of the screw is dependant on the condition of the barrel, and we manufacture, repair and recondition most types of barrels, single and twin. All work is done in-house except heat treatment which we subcontract to our specialist engineering partners. We have the capacity to handle barrels up to 6m in length from all(1) manufacturers.

We will come to your premises and do a full assessment of the condition of your barrel and provide you with a report detailing the wear along the entire length. We will also evaluate the profile, straightness, concentricity, surface finish and hardness of the screw as advise of any potential problems. We do not normally charge our local and loyal customers for this service, and consider it a necessary part of maintaining the relationship with the client.

Screws are the heart of any extruder or injection moulder. We manufacture, repair and recondition all types of screws for processing a wide variety of material from virgin pE to dry sawdust. We are able to manufacture and repair check-rings, seating washers and tips for injection moulders. We have the capacity to handle screws up to 6m in length from all(2) manufacturers.

We will come to your premises and do a full assessment of the condition of your barrel and provide you with a report detailing the wear along the entire length. We will also evaluate the profile, straightness, concentricity, surface finish and hardness of the screw as advise of any potential problems. We do not normally charge our local and loyal customers for this service, and consider it a necessary part of maintaining the relationship with the client.

Tie bar tolerances are critical to the efficient operation of injection moulders, and we are able to refurbish tie-bars by grinding, chroming and re-finishing almost any tie-bar back to original specification. We can also join tie-bars and repair damaged threads.

We manufacture and sharpen blades for all types and sizes of granulators and shredders.

We supply and repair shredders of all types and sizes from manufacturers like Untha, hi-Tech and Satrind. We recondition shredder blades at a fraction of the cost of new ones.

We make and repair nibblers (single shaft shredders) to reduce lumps to small pieces or shavings depending on requirements.

We build extruders from those with a 15mm diameter screw for use in the medical field up to 180mm diameter for use in the field of recycling, film blowing, pipe and profile extrusion, sheet extrusion etc. We have made extruders for materials as diverse as cement, sawdust, charcoal and cellulose. We also recondition and re-build extruders as well as their barrels, screws, upstream and downstream equipment.

We make and recondition dies for film blowing, flat sheet, profiles etc. For all the dies we refurbish, we remove all defects and imperfections on the die-lip and cavity and thereafter we high polish and chrome plate the die to improve product quality and increase lifespan. For sheet dies we can install our customised die lip adjusting feature that allows much greater control over the lip gap and hence control over the film thickness across the length of the die.

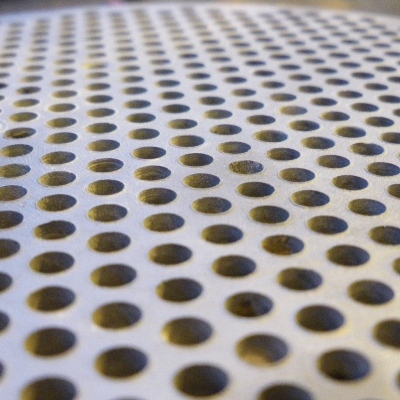

We manufacture, repair and recondition screen changers, both manual and hydraulic. We have experience with all types including, sliding plate, pivoting plate and cylindrical changers. We manufacture breaker plates according to any specification. We can manufacture spaghetti heads with any number and size of strands for water-bath pelletising lines. We also supply wet and dry die face pelletisers.

At MMTS, we have one of the longest honing machines in our area of expertise and we are able to hone bores up to 6 metres in length in-house. We offer general honing services to the public provided that our honing machine has a break in the normal production schedule for our barrel refurbishment service.

We utilise several heat treatment and nitriding companies, and due to the volumes we process, we can negotiate better commercial terms. We can include your parts for nitriding in our batches and offer you better value.

We service, repair and recondition extruder, injection moulder, shredder and granulator gearboxes as part of our regular business, but we are able to assist with any type of industrial gearbox.

We undertake repairs to all types of equipment within our capacity. We have repaired and reconditioned calendar rolls, flock cutting machines, broken screws, broken barrels, damaged and worn gearboxes, sheet dies, film blowing dies, toggle systems, hydraulic cylinders, extruders, pumps, granulators, grinders, shredders, etc, to name but a few. We would be happy to hear about your requirements and needs. All work is done in-house apart from heat treatment, chrome plating etc, which we sub-contract to specialists.

We regularly make and refurbish screws or barrels for all extrusion and injection moulding machines, including those from Merritt , American Leistritz, Maileffer, John Royle, Lester, Haitian, Creator, Davis Standard, American Barmag, Boy, Yili, Chen Yu, Johnson, Tec, Wayne, Stokes, Bekum, Trueblood, Werner & Pfleiderer, Haida, Battenfeld, Gloucester, Engel, Husky, Uniloy, Erwepa, Brabender, Fisher, New Britian, Kawaguchi, Welding Engineers, Jinhu, Windmoller & Holscher and TMC, Autoinjectors, Nokia, Berlyn, New England/CFL, Olympia, SMC, Demag, Barmag, Epco, Parker, Welex, Entwistle, Sterling Davis, Hartig, Black Clawson, Shini, Tai Shin, Van Dorn, Milacron, Negri Bossi, Nrm, Toshiba, Dr Boy, Reifenhäuser, Maillefer, Nissei, JSW, Kiefel, Moslo, Nigata, Bandera, Kraus-Maffei, HPM, Gluco, Xaloy, Kautex, Klockner Windsor, Macchi, MPM, Kolsite, Hull, Farrel, Mitsubishi, Deacon, Victor, Macchi, Natco, Egan, Mingpai, Killian, Jomar, ICMA San Giorgio, Dolci, Hoover, Cincinnati Milacron, Placo, Reed, Sumitomo, Berstorff, Arburg, Jaco, Impco, Italia, Newbury, Bausano, Akron, Nelmor and Krespi. Trademarks or brand names are the property of their respective trademark holders.

(2) We repair all shredders, grinders and granulators, including those from Durl, Moditech, Blackfriars, Nelmor, Rapid, Foremost, Alpine, Untha, Hi-Tech, Sam Chin and Queens. Trademarks or brand names are the property of their respective trademark holders.

Tie bar tolerances are critical to the efficient operation of injection moulders, and we are able to refurbish tie-bars by grinding, chroming and re-finishing almost any tie-bar back to original specification. We can also join tie-bars and repair damaged threads.