MMTS offers a wide range of engineering products to the plastic conversion and recycling industry. This includes the manufacture of barrels, screws, granulators, nibblers, complete extruders, screen changers, and a host of parts and accessories.

In the process of extrusion, screws are used to process the raw material into a usable form to make the final product required. However, the performance of the screw is dependant on numerous factors, and we design and manufacture all types of barrels, single and twin. We have the capacity to handle barrels up to 6m in length from all manufacturers (1).

We can manufacture a nitrided NiCrAl steel barrel in approximately 2-3 weeks depending on it's size and design complexity. All work is done in-house except heat treatment which we subcontract to our specialist engineering partners.

We also manufacture bimetallic barrels from imported blanks that we keep in stock. A bimetallic barrel can be made in as little as a week and they offer superior wear resistance for customers who are using particularly abrasive materials such as recycled post-consumer films, titanium whiteners , calcium carbonate fillers and glass fillers.

We have the ability to design and manufacture almost any type of extruder screw, from cross-linked polyethylene to soap and even cellulose. We can manufacture a screw in as little as two weeks in our works, including heat treatment time. Bimetallic screws can be imported in any design from our international suppliers.

In the process of injection moulding, a screws inside a barrel is used to process the raw material into a usable form to make the final product required. However, the performance of the barrel is dependant on numerous factors, and we design and manufacture all types of barrels, both bimetallic and nitrided in construction. We have the capacity to handle barrels up to 6m in length from all manufacturers(1).

In the process of injection moulding, screws are used to process the raw material into a usable form to make the injection and the forming final product required within the die cavity. However, the performance of the screw is dependant on numerous factors, and we design and manufacture all types of screws, single and twin. All work is done in-house except heat treatment which we subcontract to our specialist engineering partners. We have the capacity to handle screws up to 6m in length from all manufacturers(1).

We manufacture both replacement and custom-designed tips sets for injection moulders. If you are experiencing problems with limited shot weight, poor cushion retention and long cycle times, we can design a tip to suit your process. All our tips are made with specialised NiCrAl nitriding steel and are heat treated and/or nitrided depending on the requirements. We also make specialised ring-less PVC injection moulder tips.

If you need to replace a broken or worn nozzle or want to increase the length of your nozzle, we can manufacture a new one either according to your design or a design by our experienced team.

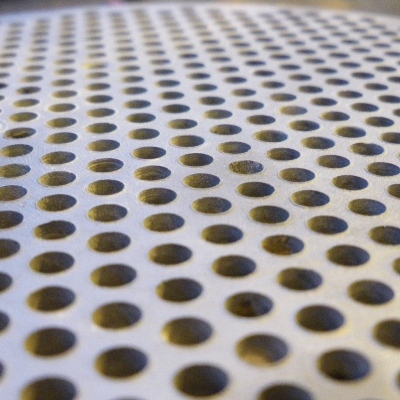

We make hardened tool steel breaker plates of any size and any number of holes.

We supply new, service, repair and recondition extruder, injection moulder, shredder and granulator gearboxes as part of our regular business. We can also assist with any type of industrial gearbox.

Rotary dough cutters are a new line of products for us in South Africa, and we have made several for a bakery in Johannesburg. They are used in the production of flat breads, pizza bases, pita breads, wraps and tortillas. We can design and manufacture a roller to cut almost any shape in your dough!

We manufacture manual and hydraulic screen changers for extruders from as small as 25mm to as large as 180mm in diameter.

If you need to replace a broken end cap or want to increase the bore of your injection moulder, we can manufacture an end cap either according to your design or a design by our experienced team.

Pitcture by Glenn McKechnie / CC BY-SA

Tie bar tolerances are critical to the efficient operation of injection moulders, and we are able to manufacture tie-bars up to 6m in length by machining, grinding, chroming and finishing to original equipment specification and quality levels.

We have manufactured numerous pipe and profile calibrators, both atmospheric and vacuum in design.